Completed Project Reference – KDT Industry

Introduction: Powering Central Asia’s Energy Future

The Rota – Çalık Energy Project in Uzbekistan is one of the most significant international energy developments in Central Asia. Designed to strengthen Uzbekistan’s energy infrastructure and provide reliable electricity for industrial and residential needs, the project represents a strategic partnership in regional power generation.

KDT Industry proudly contributed to this project by delivering industrial storage tanks, water management systems, fuel infrastructure, and steel fabrication, ensuring the facility operates with efficiency, durability, and international compliance. This project reinforces our role in global energy infrastructure solutions.

Project Scope and Objectives

Large-scale power generation projects require robust infrastructure to support continuous operations. KDT Industry’s objectives in this project included:

- Supplying fuel storage tanks for continuous power plant operations.

- Delivering water storage systems for cooling, steam generation, and safety systems.

- Providing chemical storage solutions for water treatment and operational processes.

- Manufacturing steel components and auxiliary structures for plant facilities.

- Ensuring long-term durability, safety, and global compliance.

By meeting these objectives, KDT Industry supported Uzbekistan’s vision of sustainable and reliable energy infrastructure.

Engineering and Manufacturing Excellence

Energy production requires high-performance, durable, and safe infrastructure systems. KDT Industry applied its engineering expertise and advanced manufacturing techniques to deliver:

- Fuel Storage Systems: Large-capacity tanks engineered for heavy fuel and natural gas backup systems.

- Water Infrastructure: Storage tanks supporting turbines, cooling cycles, and emergency systems.

- Chemical Storage Units: Corrosion-resistant tanks with secondary containment for treatment agents.

- Steel Fabrication: Heavy-duty industrial steel components for plant operations.

- Global Compliance: All designs and systems manufactured to meet ASME, API, ISO, and international energy standards.

Through these contributions, KDT Industry ensured the plant operates with safety, efficiency, and resilience.

Challenges and Solutions

The Rota – Çalık Energy Project in Uzbekistan presented unique challenges related to scale, geography, and compliance:

- Remote Location – Infrastructure needed to be transported and installed in a landlocked country with complex logistics.

- High Energy Demand – The facility required uninterrupted fuel and water supply to maintain operations.

- Environmental Regulations – Compliance with Uzbekistan’s environmental laws and international standards.

- Continuous Operations – Infrastructure had to support 24/7 industrial energy production.

KDT Industry’s Solutions:

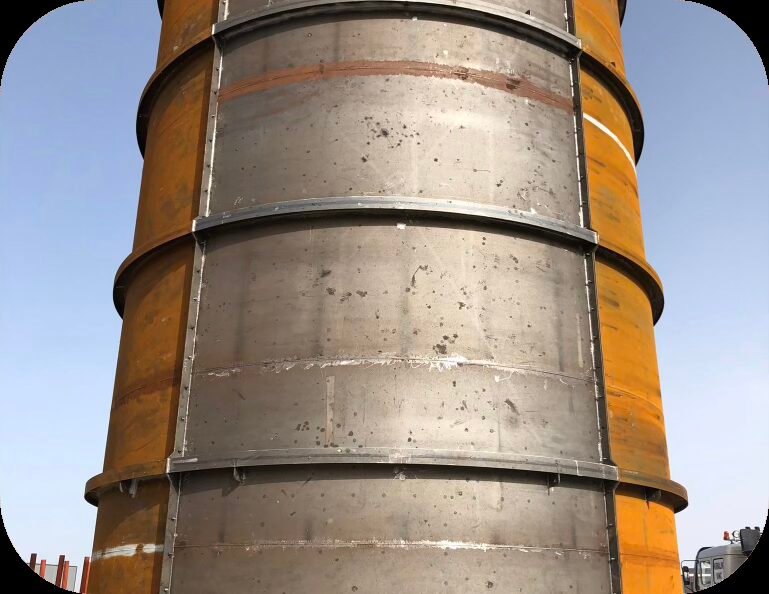

- Developed modular and prefabricated storage tanks for easier transport and installation.

- Applied eco-friendly coatings and corrosion-resistant linings for long service life.

- Installed secondary containment systems to prevent environmental contamination.

- Conducted multi-stage testing and inspections to ensure global compliance.

These solutions enabled the project to operate with maximum reliability and sustainability.

Contribution to Uzbekistan’s Energy Sector

The Rota – Çalık Energy Project is a milestone in Uzbekistan’s national energy strategy. KDT Industry’s contribution supported:

- Reliable Power Supply: Ensuring consistent electricity for homes, industries, and businesses.

- Industrial Growth: Strengthening Uzbekistan’s manufacturing and economic capacity.

- Regional Energy Security: Reducing dependence on external energy imports.

- Economic Development: Creating local jobs and supporting infrastructure modernization.

This project demonstrates KDT Industry’s ability to contribute to strategic energy projects across international markets.

Sustainability and Long-Term Value

Sustainability is critical in modern energy projects. KDT Industry integrated eco-conscious practices into its contributions:

- Durable, Long-Life Tanks: Minimizing replacement needs and waste.

- Water Recycling Systems: Reducing overall consumption in cooling and treatment processes.

- Recyclable Materials: Steel components designed with sustainability in mind.

- Environmental Compliance: Adherence to Uzbek and international environmental standards.

These practices ensured the project was delivered as a responsible and future-ready energy facility.

Why KDT Industry Was Chosen

Rota and Çalık Energy selected KDT Industry as a partner due to its proven expertise in power generation infrastructure. Key reasons included:

- Energy Sector Experience – References in thermal power plants, biogas facilities, and industrial energy projects.

- Engineering Reliability – Precision systems designed for continuous, large-scale operations.

- Commitment to Safety – Strict adherence to global energy safety and environmental standards.

- Global Reputation – Strong track record of successful projects across Turkey, Central Asia, and Africa.

This partnership highlighted KDT Industry’s ability to act as a strategic global partner in energy infrastructure.

Looking Ahead

The Rota – Çalık Energy (Uzbekistan) Project stands as a prestigious reference in KDT Industry’s portfolio. It reflects our ability to deliver world-class infrastructure for international energy projects, supporting countries in achieving energy security and sustainable growth.

As energy demand rises across Central Asia and beyond, KDT Industry is ready to provide innovative, eco-friendly, and reliable engineering solutions for future power generation facilities.

This project reinforces our position as a global leader in energy infrastructure and industrial engineering.