Completed Project Reference – KDT Industry

Introduction: Transforming Cement Production for a Cleaner Future

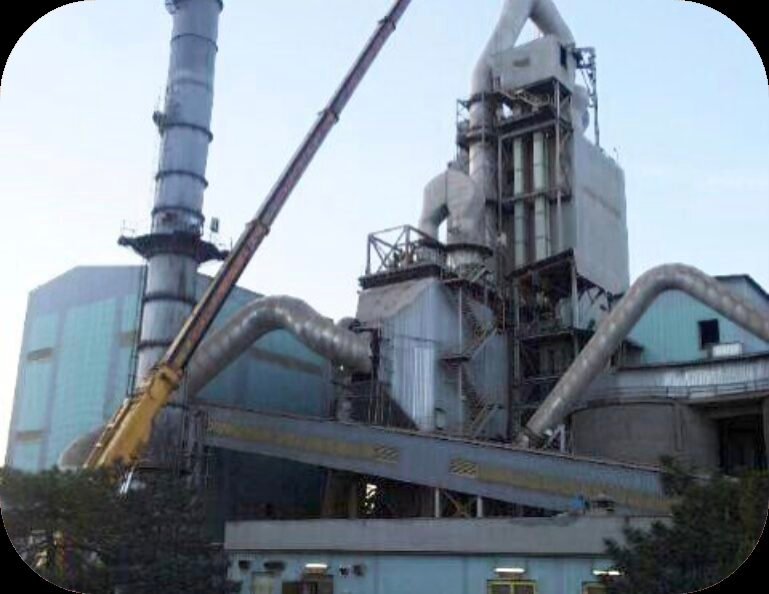

The Elazığ Cement Factory Filter Transformation Project demonstrates how traditional heavy industries can successfully transition toward environmental sustainability while maintaining production efficiency. Cement plants, by nature, generate significant dust and emissions during operations. This project modernized the Elazığ facility’s outdated filtration systems into state-of-the-art, eco-friendly technologies aligned with EU environmental directives and ISO standards.

KDT Industry contributed by supplying fabric filters, raw gas channels, chemical storage systems, and heavy-duty structural steel fabrication, enabling the plant to achieve superior emission control, operational reliability, and long-term compliance.

Project Scope and Objectives

The goal of this transformation was to reduce emissions while improving efficiency in cement production. KDT Industry’s objectives included:

- Designing and installing fabric filter systems for particulate matter capture.

- Constructing raw gas channels to direct flue gases into filtration units.

- Providing chemical storage tanks for additives used in emission reduction processes.

- Delivering structural steel frameworks for filter housings, ducting, and auxiliary facilities.

- Ensuring compliance with EU Industrial Emissions Directive (IED) and ISO 14001 environmental management standards.

These contributions transformed the Elazığ Cement Factory into a modern, sustainable facility.

Engineering and Manufacturing Excellence

The filter transformation required precision engineering and robust industrial solutions. KDT Industry applied its expertise to deliver:

- Fabric Filter Units: Pulse-jet baghouse filters designed for >99% dust removal efficiency.

- Raw Gas Channels: High-capacity ducts engineered to withstand heat and abrasive dust.

- Chemical Storage Systems: Corrosion-resistant tanks with secondary containment.

- Steel Fabrication: Heavy-duty structures for filter installations and ducting.

- Protective Coatings: Abrasion- and corrosion-resistant finishes extending equipment lifespan.

- Compliance: All systems aligned with international cement industry and environmental standards.

These solutions allowed the Elazığ plant to achieve cleaner operations and higher reliability.

Challenges and Solutions

The Elazığ Filter Transformation Project faced several technical and operational challenges:

- High Dust Loads – Cement production creates significant particulate emissions.

- Integration with Old Systems – The upgrade required compatibility with existing plant infrastructure.

- Continuous Operation – Filtration systems needed to function without interrupting production.

- Strict Regulations – Compliance with EU and Turkish emission standards was non-negotiable.

KDT Industry’s Solutions:

- Installed modular fabric filter systems for easy integration and scalability.

- Applied wear-resistant coatings to ducts and channels to handle abrasive dust.

- Deployed automated cleaning systems ensuring continuous operation.

- Delivered prefabricated steel components minimizing installation downtime.

These solutions made the Elazığ factory a model of sustainable cement production.

Contribution to Environmental Protection

The project had a direct impact on air quality and sustainability in the Elazığ region. KDT Industry’s role supported:

- Emission Reduction: Significant reduction in dust and particulate matter.

- Cleaner Operations: Helping the factory align with global sustainability goals.

- Community Health: Improving air quality for nearby communities.

- Global Standards Compliance: Meeting EU benchmarks for clean industrial production.

This project demonstrates KDT Industry’s commitment to eco-friendly transformation in heavy industry.

Sustainability and Long-Term Value

Sustainability was central to the Elazığ project. KDT Industry ensured:

- Durable Infrastructure: Long-life filter systems reducing operational costs.

- Recyclable Materials: Steel structures designed for future reuse.

- Energy-Efficient Systems: Optimized airflows reducing power consumption.

- Environmental Compliance: Full adherence to global emission and waste management standards.

These measures guarantee the facility remains a sustainable and future-ready cement plant.

Why KDT Industry Was Chosen

The stakeholders of the Elazığ Cement Factory selected KDT Industry for its expertise in industrial filtration and cement plant infrastructure. Key reasons included:

- Proven Cement Sector References – Experience in clinker lines, grinding stations, and filter transformations.

- Engineering Reliability – Tailored systems designed for high dust volumes.

- Commitment to Sustainability – Alignment with EU environmental regulations.

- Trusted Global Reputation – Recognized worldwide for heavy industry solutions.

This collaboration reinforced KDT Industry’s position as a global leader in cement industry infrastructure.

Looking Ahead

The Elazığ Cement Factory Filter Transformation Project is a prestigious reference in KDT Industry’s portfolio. It highlights our ability to deliver innovative, reliable, and sustainable solutions for heavy industries worldwide.

As environmental regulations grow stricter, KDT Industry is ready to provide next-generation filtration and emission control systems for cement plants and industrial facilities globally.

This project strengthens our reputation as a global leader in sustainable industrial engineering.