Completed Project Reference – KDT Industry

Introduction: Harnessing Water for Clean and Reliable Energy

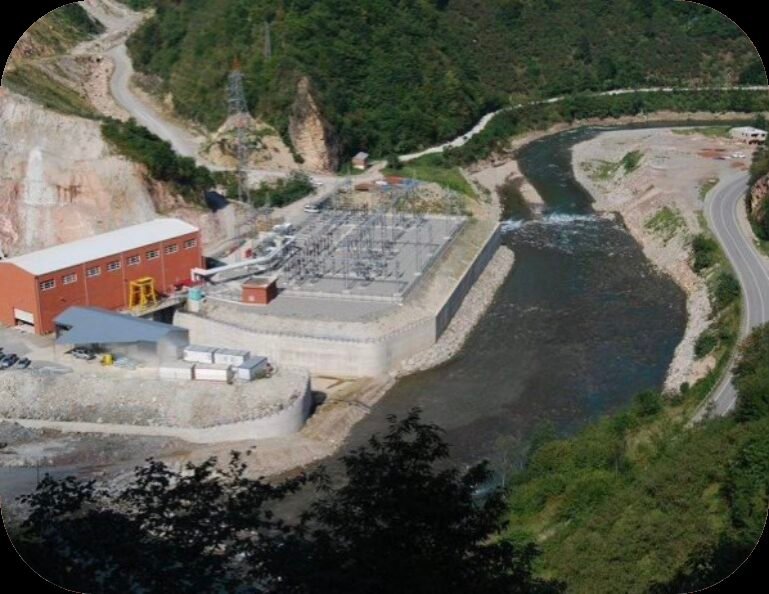

The Aslancık Hydroelectric Power Plant Project is a flagship investment in Turkey’s renewable energy strategy. Hydropower remains one of the most reliable and sustainable sources of clean electricity, supporting both energy security and environmental protection. The Aslancık project was designed to supply long-term renewable energy, reduce dependence on fossil fuels, and contribute to Turkey’s industrial growth.

KDT Industry played a significant role in this project by delivering storage tanks, structural steel fabrication, hydraulic systems, and auxiliary infrastructure, ensuring that the facility operates with maximum efficiency, durability, and compliance with international standards.

Project Scope and Objectives

The Aslancık Hydroelectric Power Plant required specialized infrastructure to support continuous renewable power generation. KDT Industry’s objectives included:

- Designing and delivering fuel and water storage tanks for auxiliary plant systems.

- Manufacturing structural steel frameworks for powerhouse facilities and support structures.

- Supplying hydraulic steel components for gates, penstocks, and turbine support.

- Installing chemical storage units for water treatment and operational additives.

- Ensuring compliance with ISO, IEC, ASME, and EU hydropower safety standards.

These contributions enabled the Aslancık facility to serve as a world-class renewable energy plant.

Engineering and Manufacturing Excellence

Hydroelectric power plants demand precision engineering and robust infrastructure to operate reliably under challenging conditions. KDT Industry delivered:

- Structural Steel Fabrication: Heavy-duty frameworks for turbine halls, spillways, and auxiliary facilities.

- Hydraulic Steel Components: Penstock supports, gates, and water flow systems built to international codes.

- Storage Systems: Tanks for fuel, water, and chemical solutions supporting plant operations.

- Protective Coatings: Corrosion- and water-resistant finishes extending equipment lifespan.

- Auxiliary Infrastructure: Platforms, pipe racks, and access systems for operations and maintenance.

- Compliance: All systems aligned with global hydropower engineering standards.

These engineering solutions ensured long-term performance, safety, and efficiency for the Aslancık project.

Challenges and Solutions

The project presented unique technical and environmental challenges:

- Geographical Conditions – The plant is located in a mountainous, water-rich region.

- High Water Pressure – Penstocks and gates required reinforced steel designs.

- Environmental Protection – Compliance with river ecosystem and emission regulations.

- Continuous Operation – Systems had to be engineered for 24/7 renewable energy generation.

KDT Industry’s Solutions:

- Delivered reinforced steel penstocks capable of withstanding extreme hydraulic pressure.

- Applied marine-grade protective coatings against corrosion and water erosion.

- Designed modular prefabricated steel components for efficient on-site installation.

- Integrated eco-conscious water management systems to reduce environmental impact.

These measures ensured the plant operated as a safe, sustainable, and resilient renewable facility.

Contribution to Renewable Energy and Economy

The Aslancık Hydroelectric Power Plant contributes directly to Turkey’s renewable energy mix and economic development. KDT Industry’s role supported:

- Clean Energy Supply: Generating renewable electricity for industries and households.

- Energy Independence: Reducing reliance on imported fossil fuels.

- Economic Growth: Supporting industrial and infrastructure expansion.

- Job Creation: Providing skilled employment opportunities in hydropower.

This project demonstrates KDT Industry’s ability to deliver infrastructure that strengthens both sustainability and economic stability.

Sustainability and Long-Term Value

Sustainability was at the heart of the Aslancık project. KDT Industry ensured:

- Durable Infrastructure: Long-life systems reducing operational costs.

- Recyclable Steel: Supporting circular economy initiatives.

- Water Efficiency: Hydraulic systems designed for optimal water flow and reuse.

- Environmental Compliance: Meeting international standards for river and ecosystem protection.

These contributions guarantee the Aslancık facility will remain a future-ready renewable energy plant.

Why KDT Industry Was Chosen

The project stakeholders selected KDT Industry due to its proven expertise in renewable energy infrastructure and heavy industrial engineering. Key reasons included:

- Proven Hydropower Experience – References in turbine support, penstock systems, and hydro plants.

- Engineering Reliability – Tailored systems built for long-term resilience under water pressure.

- Sustainability Commitment – Alignment with global renewable energy targets.

- Trusted Reputation – Recognized worldwide as a reliable partner in renewable energy projects.

This collaboration reinforced KDT Industry’s position as a leader in hydropower and renewable energy infrastructure.

Looking Ahead

The Aslancık Hydroelectric Power Plant Project is a prestigious reference in KDT Industry’s portfolio. It demonstrates our capacity to deliver innovative, eco-friendly, and durable engineering solutions that support clean energy, sustainability, and industrial growth worldwide.

As global demand for renewable power continues to rise, KDT Industry is prepared to provide cutting-edge infrastructure solutions for hydroelectric, solar, wind, and hybrid energy projects.

This project strengthens our role as a global leader in renewable energy and hydroelectric power plant engineering.